Sleek Garments manufactured millions of PPE for front-line staff in Ghana's fight against the Covid-19 pandemic.

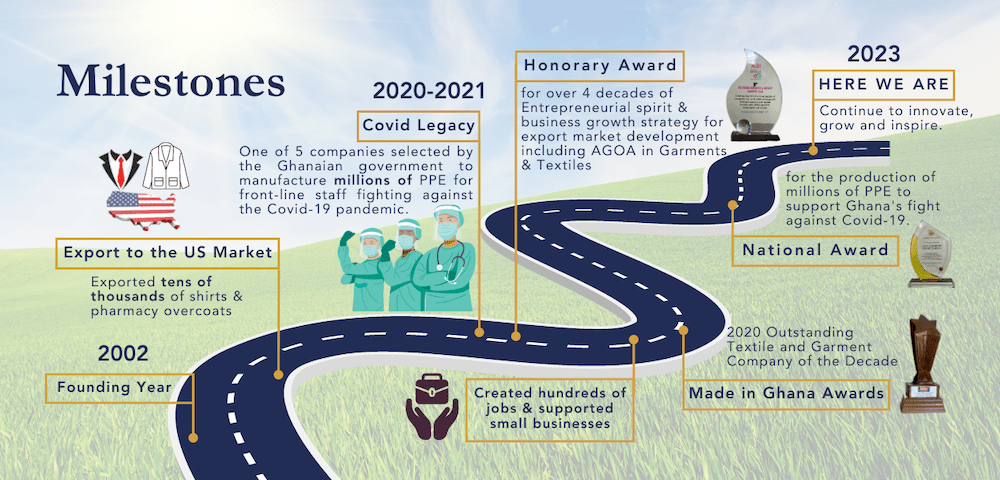

In 2020, Sleek Garments was one of the 5 companies selected by the government of Ghana to produce PPE for front-line staff in the country's fight against the Covid-19 pandemic.

In 2020, Sleek Garments was one of the 5 companies selected by the government of Ghana to manufacture PPE for front-line staff fighting against the Covid-19 pandemic.

Sleek Garments received Honorary Award for over 4 decades of Entrepreneurial Spirit and business growth strategy for export market development including AGOA in Garments & Textiles

Looking for clothing manufacturers?

Sleek Garments Export Ltd is a sister company of Sleek Fashion Ltd which was registered as a business entity in March 1979. Its training wing, Sleek Fashion Institute was established in the same year

Employees:1000 workers at full capacity Daily Output: 4,000 -10,000 depending on product Duty-free access to Markets: USA , EU & UK, Africa

Services

MANUFACTURING

We specialise in the design and manufacture of both premium boutique high-end style clothing produced products for the global retail markets.

DESIGN

Sleek Garments specialises in the design of traditional as well as contemporary patterns. Our designs are influenced by cultural and social latitudes, which have varied over time and place.

TRAINING

Sleek Fashion Institute which founded in 1979 has transitioned into Africa Institute of Creativity and Technology and it is an institute to train future fashion specialists and also as an NGO.

Its main aim is to collaborate with Sleek Garments Export Limited to impact skills in a variety of areas.

All in the details

“It is the accuracy and detail inherent in crafted goods that endows them with lasting value. It is the time and attention paid by the carpenter, the seamstress and the tailor that makes this detail possible.”

Tim Jackson

Our Production Process

Pre production (PROTOTYPES & SAMPLING)

The process begins with your idea. We guide you through the stages of making your concept a reality. Each order includes a prototype for approval, allowing you to refine your design before we commence bulk manufacture.

Pattern development

Patterns for your clothing are developed using custom dimensions or sizing references. Producing at scale and cutting to fit is our hallmark

Fabric sourcing

Fabric is sourced or produced per order to meet your requirements for composition, handfeel and budget

CLIENT PURCHASE - FULL PROCESS

- Receipt of order enquiry and client sample/tech pack

- Communication of pricing to the client

- Production of sample to client for approval

- Once sample is approved and full order received, documentation/Lc’s are set up

- Merchandising department begins procurement of fabric and trims

- Production begins

- Customs documentation and shipment

- Payment

Bulk manufacturing

Clothing manufacturing takes place on our production line, with your approved specifications forming the basis for bulk.

Quality check

We implement a 4 stage quality check process, with each item checked by an operative to identify and rectify any rare defects.

FAQ

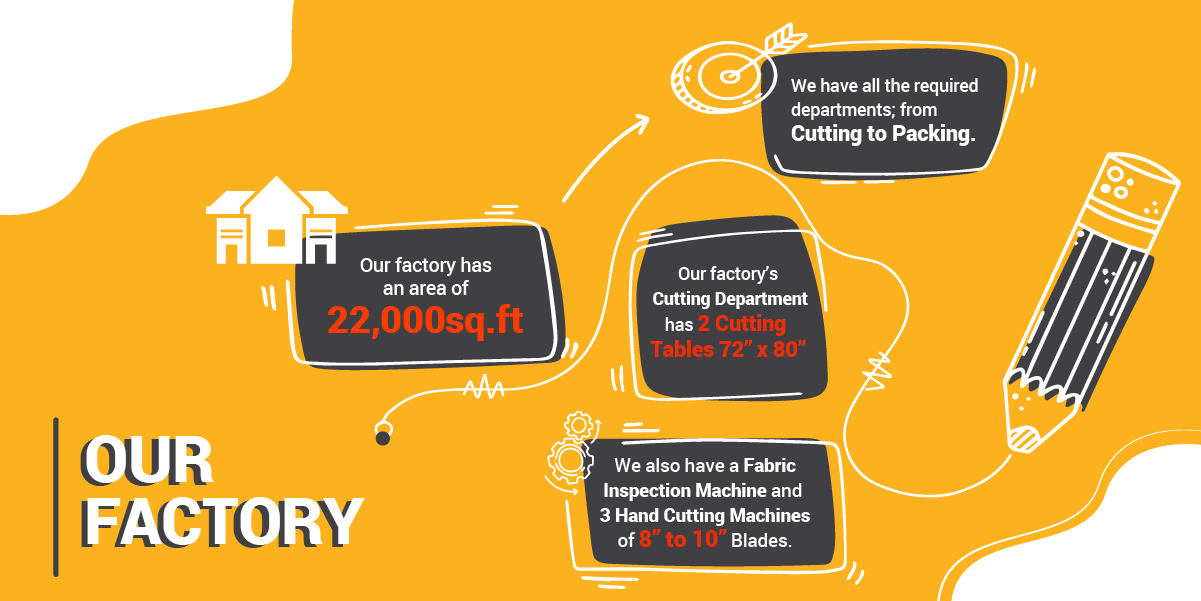

Our factory operates in the business district of Accra, Ghana. Our infrastructure and strategically placed partnerships allow us to offer competitive pricing for all garments we produce. Being based in Ghana with an Accra operation hub, we can help our customers stay ahead with all their garment needs.

Our MOQ starts from 50pcs per design, but specific requests, including colour and fabric options, can mean a different MOQ is required. Please get in touch to find out what the MOQ would be for your design. Get in touch and let’s us help make your designs come to life. Partnering you in creating jobs as you embrace our high-quality products.

We offer custom manufacturing made to your specifications. We also have a range of clothing designs where specifications such as the dimensions, fit and fabric have been pre-determined for you. Allowing for greater customisation flexibility.

Each item of clothing produced is carefully cut and stitched by industrial machinery, with each garment undergoing four stages of quality control to ensure they meet the high standards of our customers. Let’s talk about your garment, we are here to help.